NOVATOP OPEN

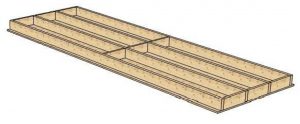

NOVATOP OPEN are panels that combine the advantages of KVH beams dimensioning and the multi-layer solid panel (SWP). The panels are an efficient and safe solution for diffusionally open wall and roof structures.

The construction consists of a bottom bearing multilayer panel (SWP) onto which beams (KVH, DUO, TRIO, BSH, I-girders) are glued in the basic axial distance of 625 mm, performing the bearing function. For reinforcement around the perimeter and around the openings, there are inserted transverse reinforcing ribs. The dimensions and the distances of the beams can be adjusted according to the requirements of the project. Connection of the boards and the ribs is carried out by gluing and cold pressing.

The degree of prefabrication is open:

The space between the beams can be fitted with thermal insulation in the production process or on site. OPEN can be closed with another areal material – diffusionally open (e.g. Fermacell, DHF, DFP, etc.).

Bottom SWP thicknesses: 27mm (9/9/9), 19mm (6/7/6).

Total heights: 227 mm, 247 mm, 267 mm and other

Standard widths: 1030, 2090, max. 2450 mm

Lengths: according to the project documentation, standardly 6000, maximum 12.000 mm

KVH dimensions (DUO, TRIO, BSH, I-girders): 200/60; 220/60; 240/60 mm and other

Standard axial span of ribs: 625 mm, the others according to the static assessment

Maximum format: 12.000 x 2450 mm (Extension of the SWP with an inlay finger joint).

Qualities of the bottom panel of the element (SWP): visual (B), no-visual (C)

INNOVATIONS

Surface finishes 2 in 1 – protective coating and final surface finish of the interior

Application

• walls, ceilings, roofs

Advantages

• large area panels of up to 12 x 2.45 m

• low weight

• high static load capacity

• exact machining according to the project

• possibility of adding thermal insulation or routes for the distribution of installations

• quick and easy assembly with high accuracy

• immediate foot traffic

• easy combination with other structural systems

• possible visual quality towards the interior

Application – photo gallery

The downloads section includes:

Technical documentation

Machining possibilities

Planning Documents

Assembly instructions

Structural details: Joints and applications